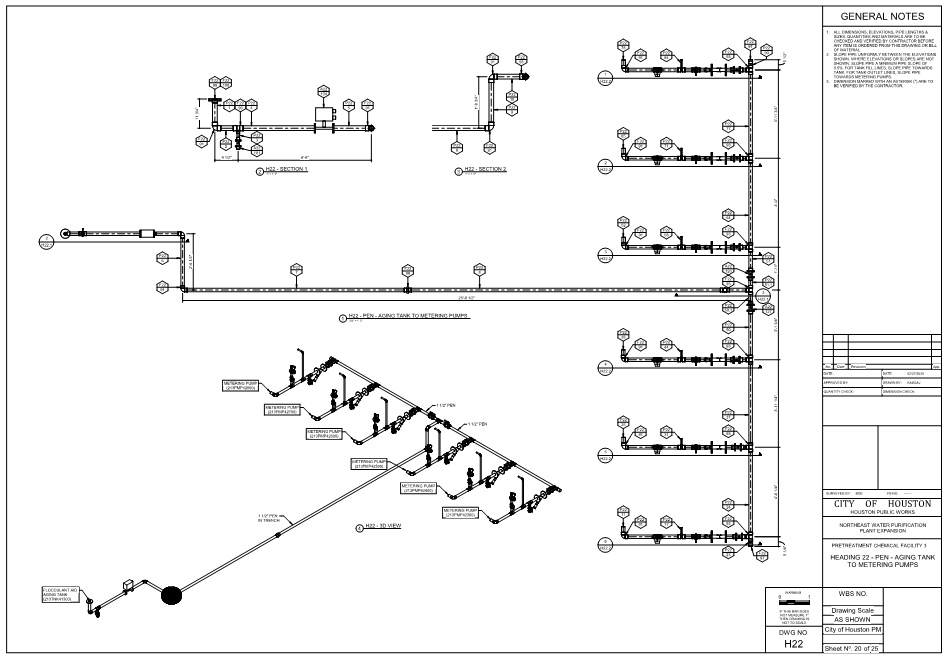

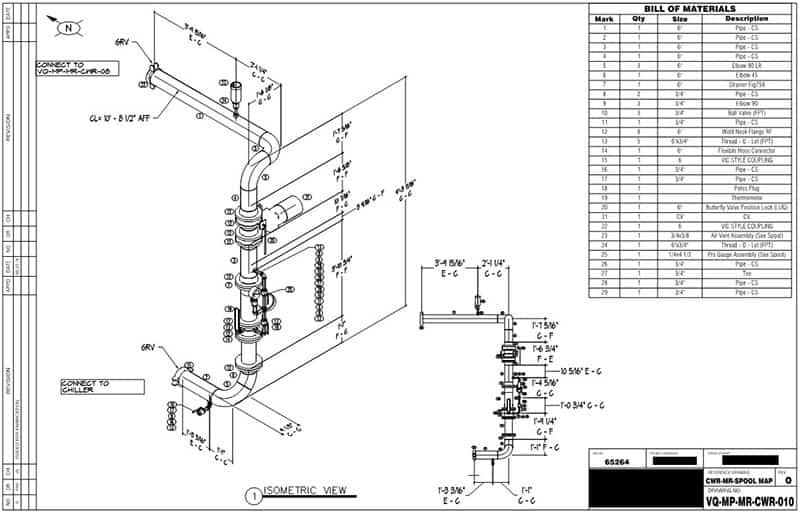

Spool Drawings Services

Spool drawings, also known as piping spool drawings or fabrication spool drawings, are detailed drawings that provide essential information for the fabrication and installation of piping systems. These drawings are commonly used in industrial plants, refineries, chemical plants, and other large-scale facilities. Spool drawings play a critical role in the construction process, guiding the fabrication and assembly of individual sections or "spools" of piping that will be installed in the final structure. By ensuring precision and efficiency, spool drawings help streamline the installation process and reduce errors in the field.