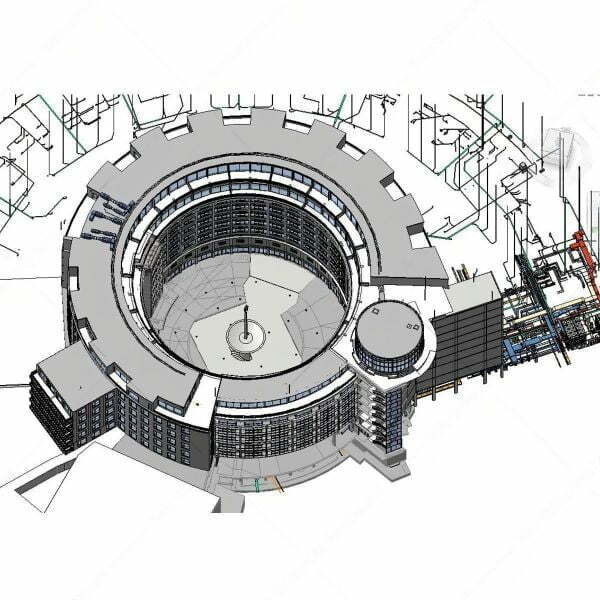

Structural Precast Modelling

We offer accurate structural precast modeling services at a quick turnaround time. We have advanced Autodesk tools such as Revit and AutoCAD. Such tools are targeted at detailing, modelling, planning, and taking complete control of all precast processes from development, design, erection, quality, and control. Our experts can handle structural precast modelling with extraordinary skills and offer fabrication level details and accurate shop drawings for structural beams, columns, insulated walls, walls, slabs, hollow cores, and filigree elements in the walls.

Structural precast services" generally refer to the design, manufacturing, and installation of precast concrete elements used in construction for structural purposes. Precast concrete is a type of construction material that is cast and cured in a controlled environment before being transported and set up on a construction site. This method offers several advantages, including improved quality control, reduced construction time, and enhanced durability.